Technical

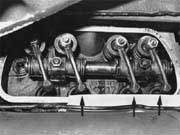

In this photo of the driver's side of the car, the engine is at TDC for

cylinder three. The front three valves (on the left with the arrows under

them) are all loose and ready to be adjusted.

In the photo of the passenger's side of the car, the engine is still at

TDC for cylinder three. The rear valve (on the left, with the arrow under

it) is loose and ready to be adjusted.

Halfway done. Turn the crankshaft 360 degrees and you will again be at TDC

with the distributor rotor pointing the other way (toward the number one

plug wire). When the motor is at TDC for cylinder one, the right three

valves on the right side of the engine (see arrows) will be ready to

adjust.

At TDC for cylinder one, the single rightmost valve on the left side of

the engine (see the arrows) will be ready to adjust.

Valve Adjustment

Story by greg Raven

It is no

secret that if you want your Volkswagen's motor to last more than five or

ten thousand miles between overhauls, you have to change the oil and

adjust the valves. Changing the oil is easy, provided you have someplace

to dispose of the waste oil (Hint: Don't pour it down a drain or dump it

out on the ground. Find a garage or service station that recycles its oil

and leave it with them.

Adjusting

the valves is a little more work, but it is no less important. As your

motor runs, the heat and the force of the valve spring pulling the valve

closed can stretch the valve stem, making the valve longer. After enough

stretching, the small amount of clearance between the adjustment screw in

the rocker arm and the end of the valve will disappear. When this happens,

the adjustment screw will begin to hold the valve open a little instead of

letting it close fully, not allowing a good seal between the valve and the

valve seat, so you lose power. Even if that were the only result of having

tight valves, it would be bad enough. Unfortunately, there is another

reason why the valve face must seat firmly against the valve seat.

Inside the

combustion chamber, there is a lot of heat created by the burning

gasoline. Some of this heat soaks into the head of the valve. The valve

has only three ways to disperse this heat: cooling due to the intake

charge, heat dissipation through the valve stem and heat dissipation

through the valve seat.

Racers and

other high-performance enthusiasts can use what is called "charge

cooling"to help keep the valves alive, but unless you are an expert

at this sort of thing, you can pretty much write off charge cooling as the

answer to your hopes for a cool running engine.

That leaves

heat dissipation through the valve stem and seat. Valve stem heat

dissipation is pretty much a function of the valve stem diameter and the

condition of the valve guide. This is on the reasons why it is so

important to have good, right valve guides.

With the

scrawny, little valve stem you find on a Volkswagen valve, however, it is

clear that a lot of the cooling has to come from planting the valve face

on the valve seat long enough and firmly enough to allow heat to transfer

from the valve head to the cylinder head.

Now that

you understand all of that, it's time to start thinking about adjusting

your valves. You are going to need some valve cover gaskets, a 13mm

wrench, a screwdriver and a feeler gauge. Check your owner's manual (or a

Bentley manual) to find out what thickness feeler gauge you should be

using. If you have neither of these sources, get a 0.006-inch feeler gauge

to start out with stock engines (some experts recommend setting valves at

0.004 inch, but to start with 0.006 is fine--it gives you some margin of

error until you get good at this.)

It helps if

you are able to get your car up in the air a little with a set of

jackstands or a hoist. Open the engine cover and manually turn the motor

until it is at Top Dead Center (TDC). IT doesn't matter whether piston one

or piston three is on the compression stroke, just find TDC.

Now, slide

under the car and pull off the valve covers. If your hands aren't strong

enough to do the trick, wrap a shop rag around the valve cover bail, grab

the two ends of the rag and pull outward and downward sharply. The bail

should snap off. Depending upon how long the valve cover has been on (and

how hot the car has been), you might have to pry the valve cover away from

the head with a screwdriver. Place the valve covers on the ground so that

they catch any dripping oil.

It should

be pointed out that Volkswagen valves are adjusted with the engine cold.

You can't drive home from work, pop the covers and do a

"quickie"adjust, then speed off for the evening. The motor must

sit long enough so that it is cool to the touch. It might not be very

convenient, but at least you won't be burning your hands on this job.

As you look

up into the engine, you can see there are four valves on each side of the

engine...eight in all. Reach up and manually check for clearance of the

four closest to you. You should find that there are two

"patterns"to which valves have clearances and which valves

don't. Either the front three valves will have clearance (and the back

valve will be tight) or the back valve will have clearance (and the front

three will be tight). I say "should" because if you have a valve

that has lost all of its clearance, it won't be loose under any condition,

but that's the situation we're trying to prevent, right?

Insert your

feeler gauge between the end of the valve stem and the end of the valve

adjustment screw. If you have never done this before, give yourself some

time to get used to the way the feeler gauge feels. The gauge has to be

held "just right" in the gap. If you twist or pull on the feeler

gauge you will get an erroneous feel for what the gap is.

You are

looking for the feeler gauge to slip between the valve stem and the valve

adjustment screw with a little resistance. If the feeler gauge falls out

when you release it, the gap is too large. If you have to force the gauge

in and then strong-arm it out, the gap is too small.

Let's

assume that by this point you have determined that the gap isn't right.

Take the 13mm wrench and loosen the jam nut on the valve adjustment bolt

for the improperly gapped valve. Use the screwdriver to change the gap

while you monitor your progress with the feeler gauge. If you want to get

really trick, many retailers offer a combination wrench and screwdriver

just for adjusting your valves. Be careful that you don't clamp down on

the blade of the feeler gauge while you are tightening up the adjustment

because you will deform the gauge material and it will be more difficult

to get a good feel for the gap.

When the

gap feels right, hold the adjustment screw with the screwdriver and use

the 13mm wrench to tighten up the jam nut.

Murphy's

Law states that if the gap feels perfect, the adjustment screw will try to

turn when you tighten the jam nut. That's what the screwdriver is there

for. It might take a couple of tries, but don't panic. Make certain to

double check the clearance after you tighten down the jam nut.

Repeat this

procedure with the other three valves. You are now half done. Go up

topside again and rotate the engine 360 degrees until the TDC mark comes

up. Scrunch under the car again and check the clearance pattern. You will

see that it has reversed itself from side to side. The three that had no

clearance on one side now have clearance and the one valve with no

clearance on the other side now has clearance as well. You can now adjust

the remaining four valves as you adjusted the first four.

It all

sounds pretty rosy in print, but there are things that can come up. If the

rocker arm isn't bolted down tight, your adjustments will be off. There is

a far more common problem, however, and it can be pretty aggravating. You

insert the feeler gauge into the gap and notice that there is too much

clearance. You turn the adjustment screw a small fraction of a turn and

suddenly there is no clearance. And no matter how long you fool with it

there isn't any middle ground; the adjustment is either too loose or too

tight.

Here's

what's happening: The ends of the adjustment screws have developed little

flat spots from misadjustments, oil breakdown or just plain age. The cure

is to pick up a new set of adjusters. They normally come with jam nuts,

which is good because they can get pretty rounded off. Replace the old

adjusters with the new adjusters and life should once again be a bowl of

cherries for you.

Clean out

the valve covers and replace the old valve cover gaskets with the new

gaskets you bought. You do not need glue to keep the gaskets in place. Put

the covers back on and snap the bail wires in place. Let the car off of

the stands and check your oil lever.

By checking

your valve adjustment every 2,500 to 3,000 miles when you change your oil,

you will help ensure that you will never fall prey to a burnt valve.